Technical Data

Precision Investment Cast Superalloy Gas Turbine Component Welding Repair

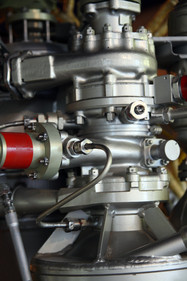

Advanced technology, precipitation-hardenable Nickel base superalloys of the high volume fraction of gamma-gamma prime type are extensively used in the form of precision investment castings for gas turbine, hot-section engine components. Such castings can exhibit as-cast defects and in-service wear in the form of surface & subsurface cavities, voids, porosity and loss of profile. Often in the past, the presence of investment casting defects and wear has been cause for rejection even for large and expensive components. One reason for this approach was that suitable welding procedures and applied metallurgy was not sufficiently advanced to produce acceptable salvage welds. Many alloys had even been considered to be unweldable. Another reason for rejecting the defective valuable investment cast components was that appropriate quality filler metals were not available.

Salvage and repair welding of advanced Nickel and Cobalt base superalloy precision investment castings, including 3rd, 4th and 5th generation materials, however, is now carried out for many alloys that have been considered to have marginal weldability. A typical welding associated problem concerns the possible formation of liquation cracking, often on a micro scale, and especially in the weldment fusion zone. Some of these materials can be subject to interdendritic local micro-segregation which also adversely influences sound weld fusion.

Salvage and repair welding of advanced Nickel and Cobalt base superalloy precision investment castings, including 3rd, 4th and 5th generation materials, however, is now carried out for many alloys that have been considered to have marginal weldability. A typical welding associated problem concerns the possible formation of liquation cracking, often on a micro scale, and especially in the weldment fusion zone. Some of these materials can be subject to interdendritic local micro-segregation which also adversely influences sound weld fusion.

Susceptibility to this form of unacceptable weld-associated defect is significantly reduced by incorporating high purity welding filler metal that has controlled low level of impurity and residual element content. USWC’s MC-GRADE®, TURBALOY® range of Nickel base superalloys such as Rene® 220 (TURBALOY® 220), Rene 41® (TURBALOY® 41), Waspaloy® (TURBALOY® 685), GTD-222® and GTD-262® to name a few are specially designed for this purpose and is widely adopted throughout the aerospace and power generation industries. This USWC aerospace range of welding filler metals is unique and demonstrates a high level of applied fundamental metallurgy. The MC-GRADE® products are a worldwide standard throughout the gas turbine industry and associated investment casting foundry businesses. Filler metal cutaneous and subcutaneous contamination is eliminated by the wire manufacturing processes giving consistently reproducible high purity weld metal transfer.

This outstanding aerospace grade of welding filler metal also copes more appropriately with inter-dendritic and grain boundary micro-segregation issues.

This outstanding aerospace grade of welding filler metal also copes more appropriately with inter-dendritic and grain boundary micro-segregation issues.

Successful welding procedures based upon MC-GRADE®quality are standard in many precision investment foundries and for subsequent turbine component maintenance repair and overhaul (MRO) salvage welding applications and are particularly applied to cast vane and blade components used in industrial turbine manufacture.

Controlled low-heat input, constricted-arc welding power sources and oxygen-free argon shielding in association with ultra clean component conditions are also essential ingredients for the application of successful MC-GRADE® filler metal welding repair procedures. Welding procedures are designed to minimise local residual stress and to produce fine grained, contaminant-free weld beads and sound fusion zone performance. MC-GRADE® high purity welding filler metals has set the world standard for critical advanced welding applications and is incorporated into many gas turbine component MRO and salvage procedures.

Rene®: Registered trademark of General Electric | Waspaloy®: Registered trademark of United Technologies Corp.

GTD-262®,GTD-222® Registered trademark of General Electric.

1-800-423-5964

1-800-423-5964